Ruud Huijer, 25 september 2015.

From my position at Beijer I regularly dig into electrical diagrams of car manufacturers. Not an easy task because each manufacturer has its own system and not all of these systems, to put it mildly, are user friendly. Not to mention the amount of wiring that is documented.

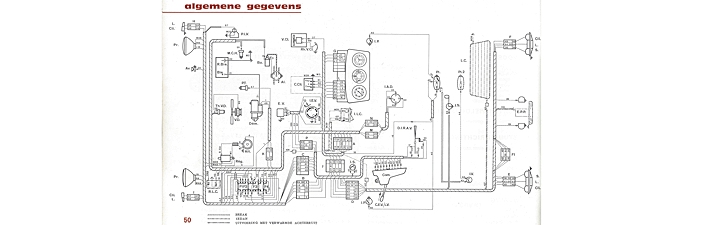

Recently I was faced with an electrical problem in my 44 year old Peugeot 204 and needed to check the wiring diagram of this car. Of course not online in any database, but simply in the owner’s manual that was in the car. The complete wiring diagram on half an A4 sheet (!), see figure). A diagram in which many parts are still recognizable by their true form. As the rear window, the headlights and the starter motor.

The entire wiring in my Peugeot requires about 60 meters of copper wire. That seems a lot, but if you realize that an average modern car contains 1.5 kilometers (!) of copper wire than it is really not that much. Twenty-five times more than in my old Peugeot!

The entire wiring in my Peugeot requires about 60 meters of copper wire. That seems a lot, but if you realize that an average modern car contains 1.5 kilometers (!) of copper wire than it is really not that much. Twenty-five times more than in my old Peugeot!

And the total amount of copper ranges from 20 kilograms in small cars to 45 kilograms in luxury and hybrid vehicles.

When in the early nineties CAN technology was introduced in cars, one of the advantages was the decrease of the number of kilometers of copper wire. Where previously each light / signal had its own wire, there was now only one wire for multiple lamps/signals. All data was transported over only a pair of twisted wires. Was this the way back to the half A4 sheet in the owner’s manual? No, not by a long shot. Due to the increasing number of computers in cars, over a hundred in a Mercedes S-Class, the number of wiring has increased significant in the past decade. I’ll be digging for a while yet at the office. Until perhaps something new is developed ….

Ruud Huijer